Fast Efficient Service & Quality Products

Industrial Gasket Manufacturer

At Harrison Industrial our team of experts have the knowledge and experience required to provide trusted solutions for any project. We manufacture customized gaskets right here in Sydney. Harrison Industrial, is a strategic partner for many of the leading names in gaskets, gasket materials and seals.

Our custom gaskets are manufactured to ensure quality, high-performance, by state-of-the-art technology and cutting-edge precision hardware at our local factory.

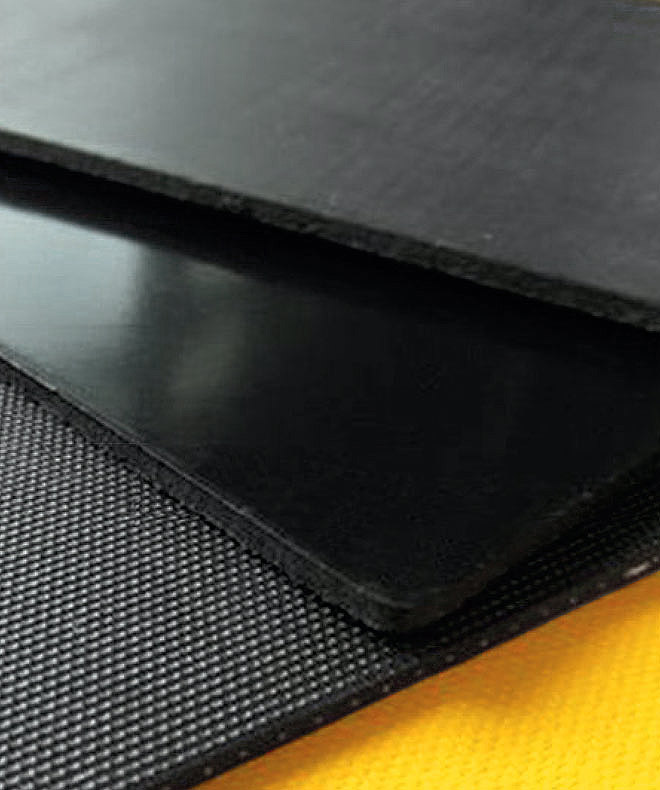

Gaskets we manufacture can be of made from a number of materials including, graphite, rubber, fibre, fiberglass and PTFE gaskets, just to name a few.

We also stock a wide range of Topog E gaskets and spiral wound gaskets.

Over the years we developed the expert knowledge and experience in manufacturing custom items for a wide range of businesses. Offering our clients high quality die-cut gaskets, waterjet-cut and hand-slice to suit multiple prerequisites at competitive prices.

A Top Supplier and Manufacturer

At Harrison Industrial we are regarded as the top manufacturer and supplier for the following products:

- Gaskets in Sydney

- Custom gaskets

- PTFE gasket

- Die cut gaskets

- Topog-e boiler gaskets

- Custom rubber gaskets

You can be sure that no matter what size of order – small or large – that you place with us, we will deliver it on time. At the same time, you can also be sure that there would be no compromise on our quality.

The Qualities We Offer as an Organisation

We are known around Sydney for our competitive prices and our capability to deliver products that are of the highest order. We are also pretty easy to do business with. We have immense experience in the industry. That is why you can count on us to provide you the best business advice as well. These are some of the reasons why we are the top name when it comes to being renowned gasket suppliers. You can also be sure that no one offers better custom gaskets in Australia. A great aspect of our products is that they can be used in most applications.

FAQ

What are different types of gaskets?

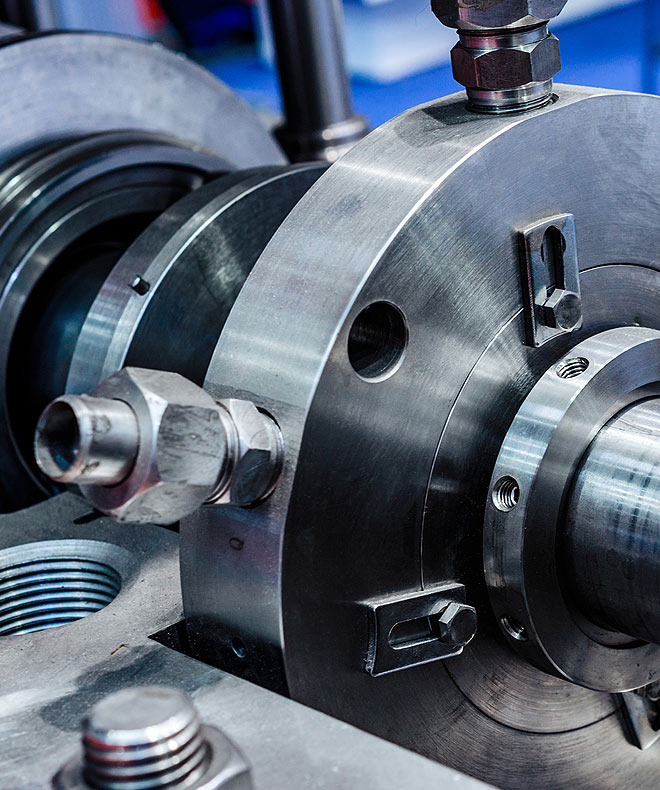

A gasket is the seal between two joining surfaces to prevent leakages. The different types of gaskets are based on their functions. The most common ones being— a gasket for pipes; gasket for vehicles; gaskets to seal pressure, temperature leakages; and custom gaskets. Based on the material used to manufacture, it is of three types mainly- rubber, cork, and non-asbestos fiber.

What is the best gasket material?

The importance of the gasket can never be ignored. Therefore, based on the place where it is to be used, there are different materials from which a gasket is manufactured.

How do you recognize a quality gasket?

As we all know gaskets vary in pricing although they are inexpensive, they can be awfully expensive to replace depending on the situation. A high-quality gasket should fit well and stop leaks and prevent contaminants between each scheduled service, and preferably longer. Many inferior low-quality products leak prematurely and can in a lot of cases force a costly unplanned shutdown. Therefore, it always pays to purchase custom-cut gaskets, for more information speak to the experts at Harrison Industrial.

Should I Use Gasket Sealant?

This is a question we have answered many times here at Harrison Industrial and as often as we asked, there is obviously no straight answer. The reason being is there are many types of applications and requirements and thousands of gaskets sealants available. Many of the gasket we have do not require sealant. Sealant is not necessary if a solid gasket is being newly to a new flanges/product. We commonly supply adhesive backing with some of our gaskets, this allows for the perfect placement and stops slippage when fitting, the adhesive backing is very stable and only adheres to what and where you want it to, it doesn’t extrude nor does it leak into places that it shouldn’t. Remember that the main issue with gasket sealant is it not required as an addition to a solid gasket and can make the replacement of old/solid gaskets sealant much harder. In Addition to this another example is using sealant on delicate flanges like aluminium, this can be extremely hard to remove leaving even more pitted and dented surface.

Why Do Gaskets Fail?

For many reasons and usually a combination of a range of factors, below is a few to consider.

- Are the flanges flat/even?

- Is the Torque Correct?

- Is the material correct? (service chemicals, resistant to fluid, temperature?)

- Is the gasket to old (all gaskets have a shelf life)?

- Are the bolts even?

- Check if the gasket too thick?

- If there is a blowout (check for pressure inconsistencies)

Request a Quote

Pricing & Information

For more information on any of our products, please complete our contact form or call to speak to one of our consultants and they will assist with your enquiry.